Table of Contents

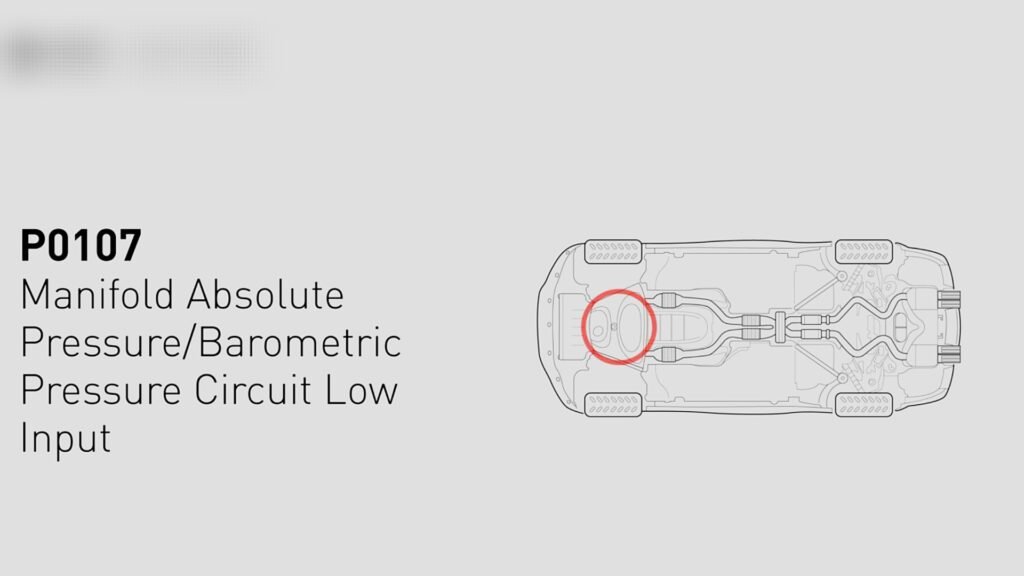

P0107 codes can cause headaches for any car owner. They appear out of nowhere, causing confusion and frustration. P0107 is one such code that drivers often encounter. But don’t worry! We’ll explore what this code means, its symptoms, diagnosis, fixes, and how to prevent it from returning.

A Check Engine light (CEL) indicates that the powertrain control module (PCM) received a reading from a sensor that was out of specification, registering a trouble code. Furthermore, a scanner or code reader device can be plugged into a diagnostic connector under the dash to access trouble codes (a service that Advance Auto Parts offers for free).

Read This Article:

Top Best Car Lifts in the World

Introducing standardized OBD-II diagnostics across brands and models has taken a lot of guesswork out of troubleshooting. It gets tricky when reading between the lines and interpreting the trouble code.

When looking at a code alone, misdiagnosing a problem and replacing unnecessary parts can be easy. Our Check Engine Light series takes on standard trouble codes and explains their meaning and how to fix them.

BAROMETRIC PRESSURE CIRCUIT LOW INPUT MANIFOLD ABSOLUTE PRESSURE SENSOR: WHAT P0107 Code and IT MEANS

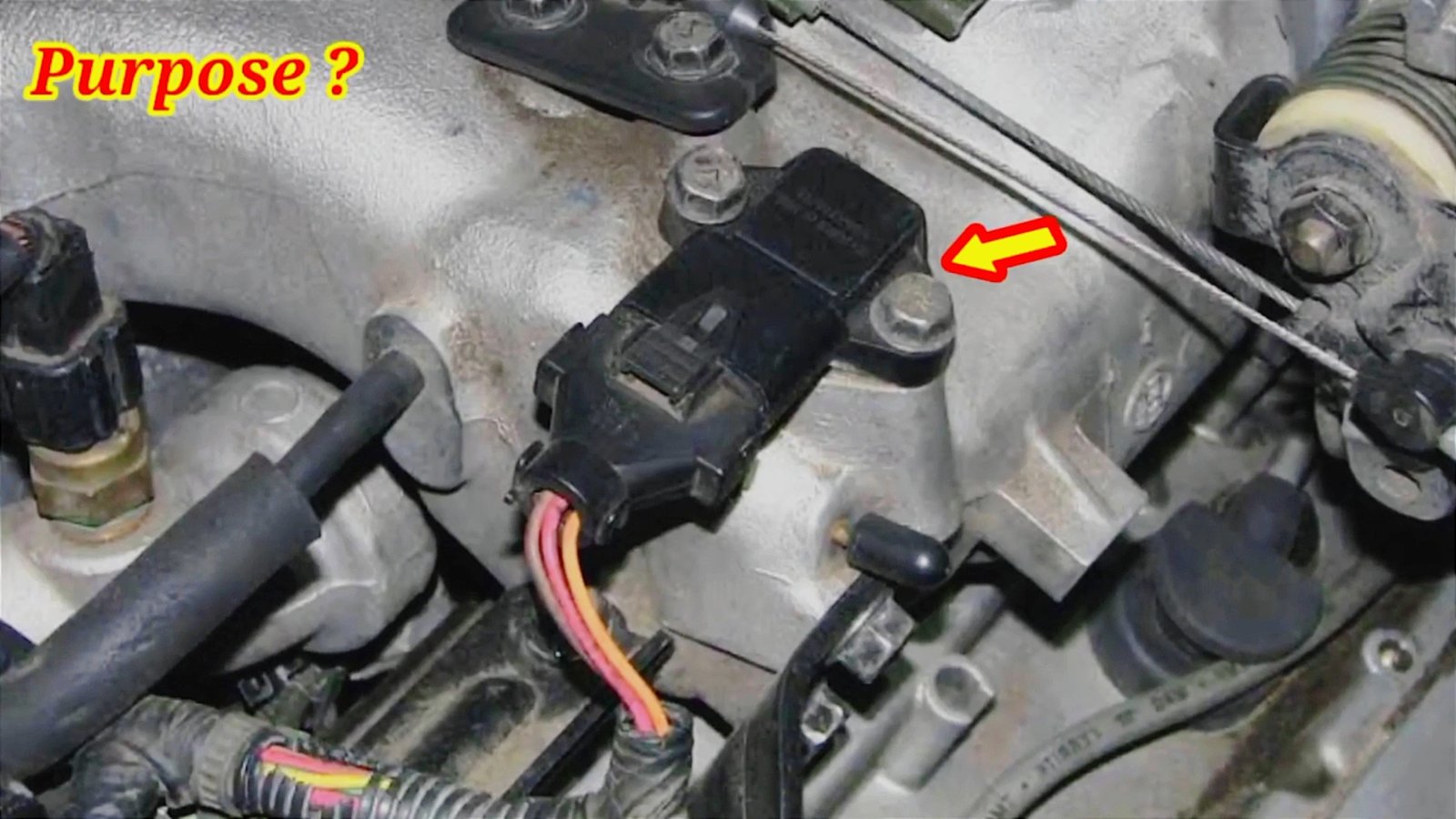

Let’s begin by explaining what the manifold absolute pressure (MAP) sensor does.

A vacuum exists in the fuel system and intake manifold during engine operation. MAP sensors measure the atmospheric pressure outside the engine, compare it to the vacuum in the intake manifold (which increases with load and throttle position), and transmit this information to the PCM. A PCM calculates air density entering the engine and adjusts fuel metering and ignition timing accordingly.

A P0107 code indicates that the MAP sensor’s reading is lower than usual. A minimum reading of 0.5 volts indicates the sensor is faulty, and anything other than that shows wiring problems.

Read This Article:

Halogen H4 Bulb – Head Light Bulb For All Cars – Super White

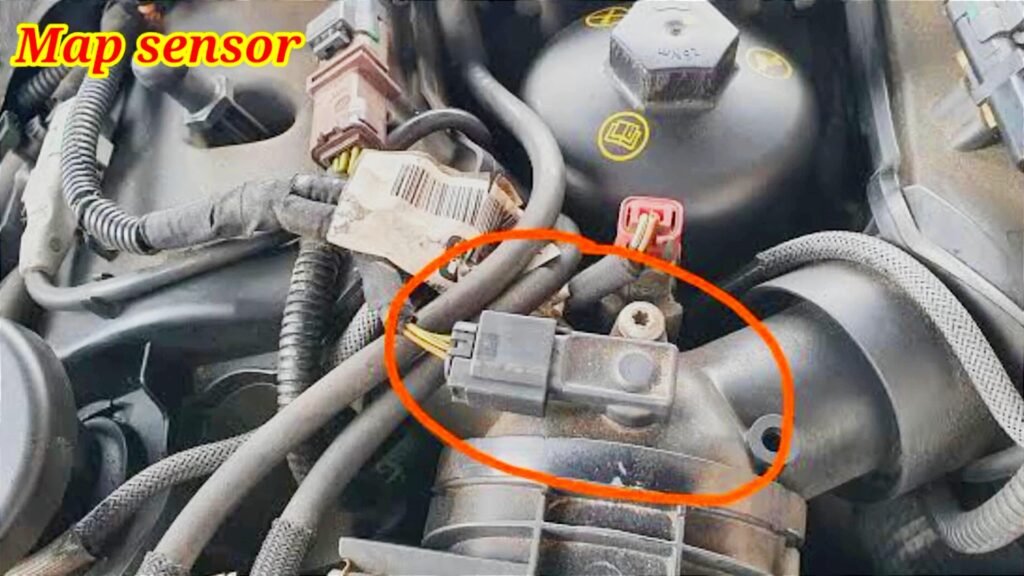

The MAP sensor can usually be accessed easily on most vehicles. Usually, it’s located on the intake manifold, the firewall, the fender well, or under the dashboard. The sensor is often found on the intake manifold, not far from the throttle body.

SYMPTOMS

A bad MAP sensor reading can affect fuel delivery, resulting in one or more of the following problems:

- Surging

- Rough running

- Rough idle and stalling

- Rich-running condition and black exhaust smoke

- Lean-running condition

- Poor fuel economy

- Hard starting or no start

- Detonation, misfire

HOW WILL IT AFFECT ME IF I IGNORE IT?

When you ignore a P0107 code, your car will likely stop starting altogether. PCMs might also put the engine in limp-home mode, where power is automatically reduced, and speed is limited to about 30 mph to avoid further damage. If this continues, you could also damage the catalytic converter as well.

DIAGNOSTIC AND REPAIR

You should use a scanner to clear the code(s) from the PCM first. Next, test the vehicle to see if the P0107 code returns. These related codes (along with P0068 and P0069) may also appear:

- P0105: MAP sensor circuit malfunction.

- P0106: MAP sensor circuit, range, or performance issue.

- P0108: MAP sensor circuit, high input.

- P0109: MAP sensor circuit, intermittent failure.

If the error code does return, perform a thorough visual inspection around the sensor. If the sensor is connected to the intake manifold by a rubber vacuum line, look for kinks, dry rot, cracks, swelling, softening, or hardening. Because these lines are exposed to high temperatures, oil, and fuel, they are prone to aging and weathering.

Ensure the sensor’s electrical connections are tight, clean, and not corrupted or damaged. It is also important to note that problems with the throttle position sensor or other vacuum lines can mimic the symptoms of a bad MAP sensor and even result in a P0107 code. A better approach than just replacing the MAP sensor indiscriminately is to troubleshoot it.

The MAP sensor uses a three-wire connector, so you should check the reference voltage first.

IMPORTANT ADVICE: If your multimeter impedes 10 megohms or less, you should be able to protect other sensitive electronic circuits and processors behind the scenes.

Here’s how you can check the voltage reference:

- Ensure the key is turned on, but wait to start the engine.

- Put the multimeter on the direct current scale at 10V.

- The sensor should be reading around 5 volts when backprobed.

- If you don’t get a 5-volt reading, check the reference voltage. In the absence of reference voltage, look for an open circuit – if not, the problem is at or before the PCM.

Check the voltage of the signal now:

- Remove the vacuum hose from the sensor.

- Connect a handheld vacuum pump to the sensor, but do not pump it yet.

- The red probe on the multimeter should be used to back probe the signal on the electrical connector (the black probe should be grounded to the negative post on the battery or any metal surface on the engine if it is metal).

- Using a T-pin, you can back probe the connector instead of stabbing the probe directly into a wire.

- When you turn on the ignition key but don’t start the engine, the voltage should read 4.5-6 volts.

- Using the vacuum pump, create about 5 in-Hg of vacuum. The voltage should be about 3.75 volts.

- Once the vacuum is built, the voltage should drop to around 1 volt using the pump.

MAP SENSOR REPLACEMENT

When troubleshooting indicates the sensor has failed, replacement is relatively straightforward. In some vehicles, the sensor is easy to get to; in others, it might require removing components.

- Remove the negative cable from the battery.

- Remove the MAP sensor (usually held in place with screws or Torx bolts) by disconnecting the sensor’s electrical connector.

- The vacuum line on the sensor and the manifold must be disconnected.

- Using the old vacuum line as a guide, cut the new line.

- Connect the vacuum line to the sensor and manifold.

- Connect the sensor’s electrical connection again.

- Sensor installation is required.

- You should reconnect the negative battery cable, clear the code if necessary, and road-test the vehicle.

Conclusion

While dealing with the P0107 code can be daunting, the correct knowledge and approach can make it manageable. Understanding the causes, symptoms, diagnostics, and fixes associated with this code can prevent potential headaches and keep your vehicle running smoothly.

FAQ’s

Can I continue driving with a P0107 code?

While driving with a P0107 code may be possible, it’s not recommended as it can further damage your vehicle’s engine and emissions system.

How much does it cost to fix a P0107 code?

The cost of fixing a P0107 code can vary depending on the underlying cause and the extent of the repairs needed. A mechanic can provide an accurate estimate.

Can a P0107 code cause my car to fail an emissions test?

Yes, a P0107 code can affect your vehicle’s emissions output, potentially causing an emissions test to fail.

Will disconnecting the battery reset a P0107 code?

Disconnecting the battery may temporarily clear the code, but it won’t fix the underlying issue causing the P0107 code to appear.

How often does a P0107 code occur?

The frequency of a P0107 code’s occurrence can vary depending on the vehicle’s make and model and its maintenance history. Regular upkeep can help prevent its recurrence.